Metal Fabrication

TiG Welding · MiG Welding · Spot Welding · Subassemblies

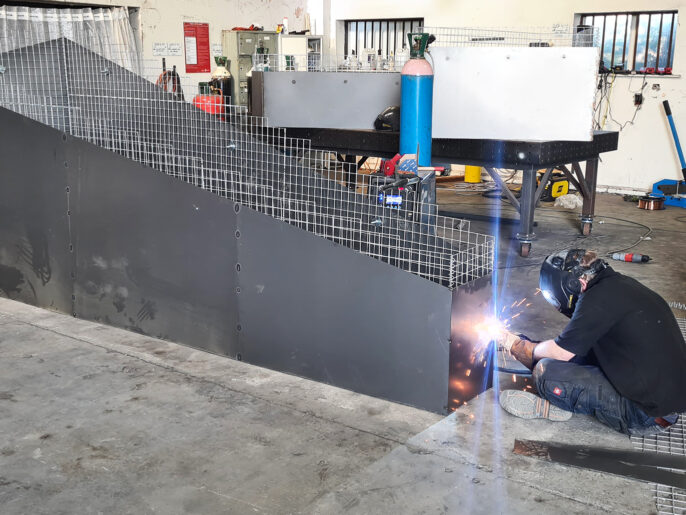

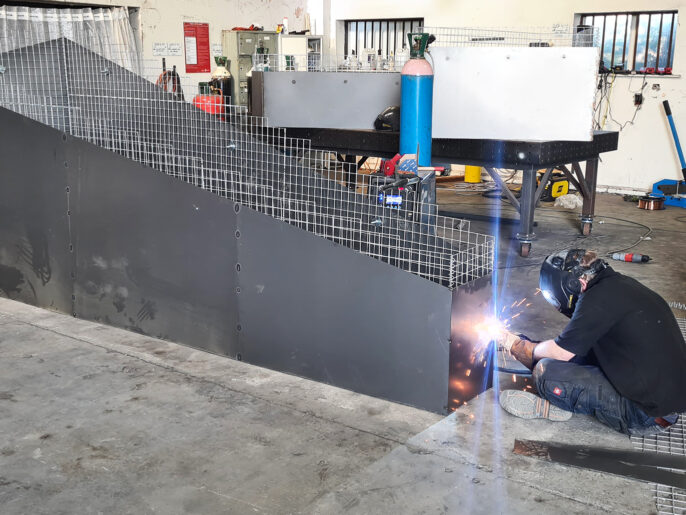

Expert welding starts in the Northeast. It starts with MorFabrication.

Welding and fabrication can go hand in hand, or you can choose to use these as stand-alone services. However, whatever you need, and whatever you choose, when you work with MorFabrication, you will always receive the highest quality service.

Fabrication at its finest

Bespoke fabrication is our expertise; whether we're working with mild steel, corten steel (weathering steel), all grades of stainless steel, copper, or titanium, we produce the product you want, meeting all design specifications and criteria.

From structural steelwork for commercial businesses, handrails, balustrades, staircases, retail storefronts, and more, we can help with it all.

Creating bespoke metal structures by using a range of fabrication techniques such as cutting, bending, welding, and assembling, metal fabricators work to a drawing to create the product.

How does MorFabrication add value?

How does MorFabrication add value? We work from your design or design your product concept for you.

Creating products from quality raw materials, we can also produce multiples of items, mass producing the fabricated product, helping to bring costs down and generate significant efficiencies for you.

Experts in fabrication and welding:

- We can create and manufacture bespoke custom-made products

- We're versatile, creating many different products for various industry sectors

- We save you time, resources, and money.

- We're creative and innovative.

What is welding?

Welding is a fabrication process that ultimately joins two metals together. There are two distinct categories of welding, commercial and residential.

Commercial welding involves more heavy industrial techniques with typical projects and tasks surrounding pipe welding.

Residential welding, however, can cover various welding tasks, such as fixing gates, car parts, etc.

At MorFabrication, we have various welding techniques at our disposal, including GTAW (TIG), GMAW (MIG), and SMAW (MMA or Stick).

We also understand the importance of selecting and working with the right filler welding material to match the parent material, for example, cast iron, various grades of stainless steel, hardox or mild steel, etc.

Benefits of fabrication

The fabrication of mild steel and stainless-steel offers strength and durability, making it an excellent solution for retail and commercial environments.

Steel is also renowned for its ability to withstand greater pressures and heat. It is also extremely sustainable., aesthetically different, and cost-effective.

Working with MorFabrication, we maximise these benefits and ensure the structural integrity of all projects.

With over 3,500sq ft of workshop space, we continually look to invest in new technology and equipment to support the development of fabrication and welding and what these processes and engineering capabilities can achieve for our customers.

Helping you with your next project

Steel and sheet metal fabrication plays a vital role in manufacturing across all industries, and we enjoy being part of the creative journey.

Whether you need a simple and straightforward gate repair or a more complex project supporting larger machinery, look no further.

Covering all areas in the Northeast such as Newcastle, Sunderland, Teeside, Darlington, Durham, Seaham, Tyne and Wear, Hartlepool, and Northumberland – if we’ve missed your area, don’t worry, call us on 0191 8162718 / 07825 909 669, and we’ll be happy to help.

Want to know more? Check out some of our projects HERE.

Expert welding starts in the Northeast. It starts with MorFabrication.

Welding and fabrication can go hand in hand, or you can choose to use these as stand-alone services, and our team will be happy to support you at every stage.

At Morfabrication, we can help you with short-run or high-volume fabrication solutions with our industry-leading custom metal fabrication services.

Whatever you need and whatever you choose, when you work with us, you will always receive the highest quality service and the best quality products.

Discuss your metal project with our team today.

How we work

We work with a wide range of businesses across various industry sectors, producing high-quality, custom metal fabrication products (make sure to check out our case studies to see some of our recently completed projects).

Offering sheet metal works covering:

- Welding

- Folding

- Cutting

- Bending

- Laser Cutting

- CNC profiling

- Finishing

- Assembly

- And more.

Handling all custom metal fabrication projects, we ensure all component parts are specific to your requirements.

We know that sheet metal contractors require specialist equipment and knowledge to produce your custom metal fabrication parts. That’s why we use the latest equipment and the best and most appropriate materials perfectly suited for your application.

Call us now to see how we can help you.

Metal Fabrications at their finest

Welding and fabrication can go hand in hand, or you can choose to use these as stand-alone services, and our team will be happy to support you at every stage.

Bespoke fabrication is our expertise; whether we’re working with mild steel, corten steel (weathering steel), or all grades of stainless steel, copper, or titanium, we produce the product you want, meeting all design specifications and criteria.

From structural steelwork for commercial businesses handrails, balustrades, staircases, retail storefronts, and more, our metal fabricators can help with it all.

Creating bespoke metal structures by using a range of fabrication techniques such as cutting, bending, welding, and assembling, our metal fabricators work to your drawings to create the ideal final product.

Advantages of metal fabrication and working with a steel fabricator include:

- Use and access to specialist equipment and technology – reducing manufacturing costs

- In-depth product analysis – we shape metal to your specifications and help to mitigate risk

- We only use the highest quality materials, leading to increased product performance for you

- We’re skilled professionals who pay attention to detail – compliant with all industry standards

- Efficient manufacturing processes – we help to keep your production line moving, meaning shorter lead times.

We understand there is no one-size-fits-all in sheet metal fabrication UK; that’s why we’re proud to provide our customers with a one-stop fabrication shop. Working closely with you at every step of the fabrication process, we ensure you get the right services at the right time to meet your individual requirements.

How does MorFabrication add value?

We work from your design or design your product concept for you.

Creating products from quality raw materials, we can also produce multiples of items, mass producing the fabricated product, helping to bring costs down and generate significant efficiencies for you.

Our team of expert welders bring invaluable knowledge and experience to the team. What’s more, we’re fully certified, carry the highest quality certific

Metal welding near me

Experts in fabrication and welding:

- We can create and manufacture bespoke custom-made products

- We’re versatile, creating many different products for various industry sectors

- We save you time, resources, and money

- We’re creative and innovative.

Customising our approach to suit any project, we work hard to accommodate all requests and specifications.

Bespoke steel fabrication from local expert fabricators in Newcastle

Sheet metal fabrication process

Punching – metal sheets are hit with force and high pressure to create specific shapes, create holes, etc, relevant to the set specification.

Hot extrusion – working at high temperatures, hot extrusion forces metal through dies to manufacture cross-sectional profiles.

Welding – fusing two pieces of metal together with the use of specialist equipment and high temperatures.

Folding/bending – applying force to shape metal sheets into their set requirements.

Laser cutting – an expensive but highly effective method of cutting steel metal.

Casting – filling a specific mould with the appropriate molten metal material and allowing this to set.

Finishing – this is the final step in the fabrication process and can cover elements such as sandblasting, painting, and powder coating.

What is the difference between metal welding and metal fabrication?

Metal fabrication is where specialist metal fabrication companies will use a series of processes, such as bending, cutting, welding, etc. to create a product out of metal.

Welding is one of the many activities within the fabrication process.

Welding is a fabrication process that ultimately joins two metals together by applying heat, pressure, or both. It is extremely specialist and requires specialist tools, equipment, and knowledge.

There are two distinct categories of welding, commercial and residential.

Commercial welding involves more heavy industrial techniques with typical projects and tasks surrounding pipe welding.

Residential welding, however, can cover various welding tasks, such as fixing gates, car parts, etc.

Welding is an incredibly versatile part of the fabrication process, allowing you to work with metals of varying degrees of thickness. We can create a strong, lasting bond on everything from 26-gauge metal sheets to much thicker structural plates.

At MorFabrication, our sheet metal contractors have a variety of welding techniques at their disposal, including TIG (creates the weld using non-consumable tungsten electrodes), MIG (wire is fed with a consumable rod through a continuous spool of electrode wire), and ARC (uses electric currents and welding rods to join metal surfaces together).

Choosing the right welding technique can be vital to ensure that we can increase speed and job efficiency so we can improve lead times for you.

We can weld:

- Carbon steel

- Stainless steel

- Aluminium

We also understand the importance of selecting and working with the right filler welding material to match the parent material, for example, cast iron, various grades of stainless steel, hardox or mild steel, etc.

If you’re searching for `steel fabrication near me` look no further than the team at Morfab. Contact us today to see how we can get your project off the ground.

Steel fabrication you can trust

Steel and sheet metal fabrication play a vital role in manufacturing across all industries, and we enjoy being part of the creative journey.

Whether you need a simple and straightforward gate repair or a more complex project supporting larger machinery, look no further.

Covering all areas in the Northeast such as Newcastle, Sunderland, Teeside, Darlington, Durham, Seaham, Tyne and Wear, Hartlepool, and Northumberland – if we’ve missed your area, don’t worry, call us at 0191 8162718 / 07825 909 669, and we’ll be happy to help.

Want to know more? Check out some of our fabrication projects and metalwork HERE.

BS EN 1090 Certified |

ISO 9001 certified |

|---|---|

|

|

| Morfabrication UKCA FPC Weld Certificate | Morfabrication UKCA FPC Certificate | Morfabrication QMS Certificate |

Browse our range of services

Design & Engineering

from concept to CAD designs to precision engineering processes – we offer it all.

Project Management

collaboration, open and honest communications, and a tight yet flexible schedule are the key to our success.

Fabrication

bespoke fabrication and welding that allows for unique custom-made products to be created.

Forming

bringing creativity to sheet metal shaping.

CNC Profiling

increase accuracy, improve quality, and reduce lead times with advanced cutting technology and a team with years of experience.

Finishing

from powder coating to copper finishing, wet spraying, chrome plating, and metal polishing, we can provide you with the perfect finish.

Dispatch & Assembly

providing transportation and logistics across the UK, we can also assemble and install on-site.

Residential work

from staircases to balustrades, gates, garden accessories, and water features our residential work continues to push creative boundaries.