Sheet metal is the general category we use for metals; however, sheet metal does come in varying thicknesses and material types – allowing you to choose the best one suitable for your project requirements and specifications.

However, two of the main reasons why sheet metal is so popular is due to the excellent structural properties it can provide and it is (if we do say so) aesthetically pleasing.

At Morfabrication, we work with various types of sheet metal, ranging from:

- Aluminium

- Steel

- Galvanised steel

- Stainless steel

- Copper

- Brass, and

- Bronze.

Throughout this post, we look at the characteristics of steel, the different types of materials, and the various uses for each metal type.

What is Sheet Metal?

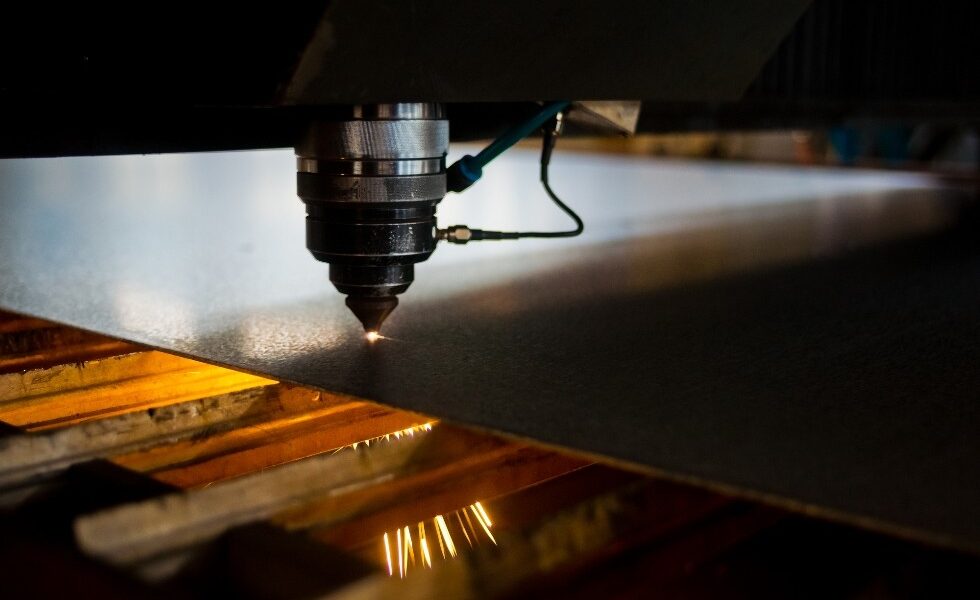

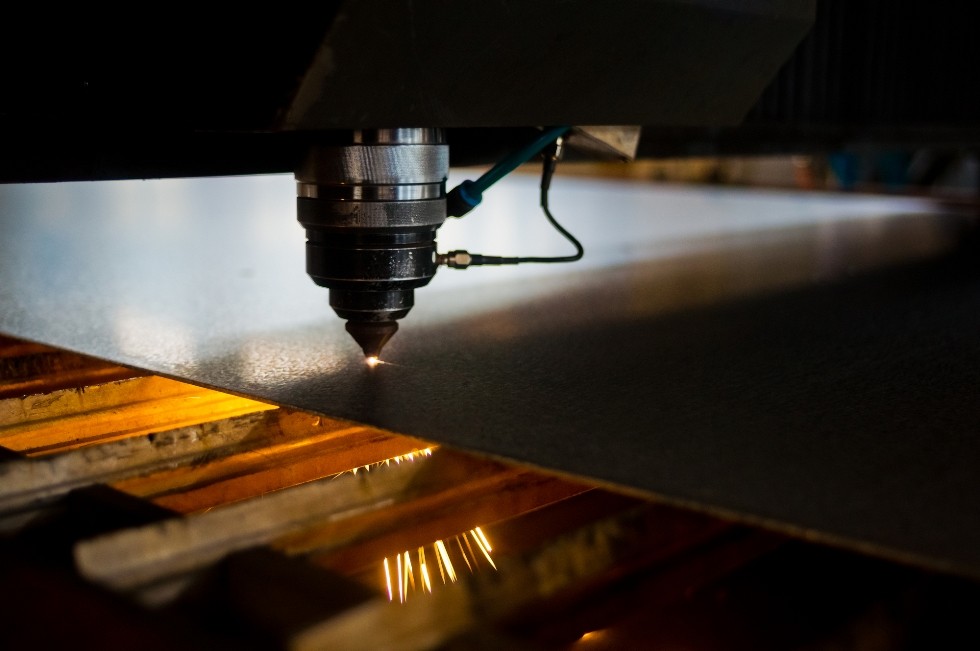

Sheet metal fabrication is an industrial process of forming and manufacturing metal into thin, flat pieces, which can then be cut and bent into the desired shape.

Sheet metal is also a versatile and workable element, allowing you to design and construct metal components and parts as required.

This means that when it comes to sheet metal uses, this can be for a variety of things, from traditional to new and demanding applications.

Applications such as cutlery, surgical equipment, architectural metal structures, use in construction, the automotive sector, aerospace, and so much more.

The fabrication process of `bending` is what we use and apply to achieve the desired results, and we cover more of this in our post on “what is sheet metal bending,” highlighting the importance, benefits, and just what’s involved.

However, sheet metal uses do vary depending on the type of material you opt for, as certain types of metal have particular resistance properties, making them suitable for specific applications to meet set performance standards.

The types of sheet metal materials include:

Carbon steel sheet – used in general sheet metal fabrication; with carbon steel, you will still require coating or some form of finishing after fabrication to prevent corrosion. However, carbon steel is a good choice if you’re looking for a sheet metal that is versatile, cost-effective, and provides good tensile strength when compared to copper and aluminium.

Galvanised steel sheet – coated with zinc oxide on the outside surface of the steel, the galvanisation process helps to protect steel sheets from rusting, making it ideal for automotive parts and objects exposed to water such as irrigation pipes, buckets, marine vessels, etc.

Stainless steel sheet – more expensive than carbon and galvanised steel, stainless steel offers enhanced corrosion resistance, making it suitable for critical applications within sectors such as aerospace, pharmaceutical processing equipment, and food handling equipment. Stainless steel is popular for commercial and residential steel requirements due to its aesthetic appeal.

Aluminium steel sheet – when weight is of concern, this is the right choice of metal for you. Resistant to corrosion and lightweight, aluminium is a superb option for marine structures, boat components, cookware, and automotive and aerospace parts. It also offers thermal and electrical conductivity and is fully recyclable, supporting sustainability standards.

Copper steel sheet – copper is a great electrical conductor; it is aesthetically pleasing and has good malleability. This makes it suitable for battery systems and often used in home décor and other forms of artwork.

Sheet Metal Uses

The potential uses for sheet metal covers a broad range of industries and applications, for example, used in:

Agriculture – machinery and equipment within this sector must be durable and able to withstand heat and wear in all weather conditions. Remaining efficient at all times, sheet metal needs to be reliable and of high quality for engine components, body kits, fenders, agricultural fan cowls, etc.

Automotive – sheet metal in this sector is used to manufacture or repair vehicles because steel is cost-effective, easily formed to specifications, safe, and reliable. There is also a requirement to meet industry standards, so sheet metal for this sector will go through rigorous quality checks, ensuring that it is fit for purpose.

Electrical – perfect for retail solutions such as tills, gaming stations, lighting solutions, power generation, solar energy systems, power testing products, and even air conditioning units. Sheet metal used in these instances will be monitored and tailored to each unique specification.

Healthcare – sheet metal fabrication plays an important role in the equipment required by the healthcare sector, especially stainless steel. Providing strength, a high level of corrosion resistance, and is rust-proof – ideal for strict hygienic environments. Tested for strength, suitability, and functionality according to legislative requirements, stainless steel fabrication in the healthcare sector is essential.

Sheet Metal Fabricators

We supply a wide range of sheet metals suitable for various applications and industry sectors. We maximise the benefits of sheet metal fabrication, passing these benefits on to you, the customer, so the project is high quality and incredibly durable.

In addition to sheet metal, we also provide a range of fabrication services, helping manufacture any component part or metal structure you require. We’re with you every step of the way – offering you quality, durability, and efficiency at every stage.

So, if you’re looking for a sheet metal fabrication company you can trust, call us on 0191 816 2718 or email your sheet metal requirements to info@morfabrication.com.