Choosing a good, experienced, and professional metal fabrication company can be difficult.

Not because there are not many to be found, but because there could be too many in your area – and how do you know the good from the average to the downright `must avoid`?

It’s more than just price (although we know this is a significant factor). It’s a range of factors and considerations that enable you to meet your business requirements.

You want to work with a team of metal fabricators that can meet your project demands, work to agreed deadlines, and provide you with a cost-effective and high-quality end product.

Innovative fabricators are always striving to gain new qualifications, invest in new equipment to support production, and continually train and learn to meet industry demands.

However, not all do.

So what should you look for in a good fabricator, and why is it important to do your research first.

Metal Fabrication

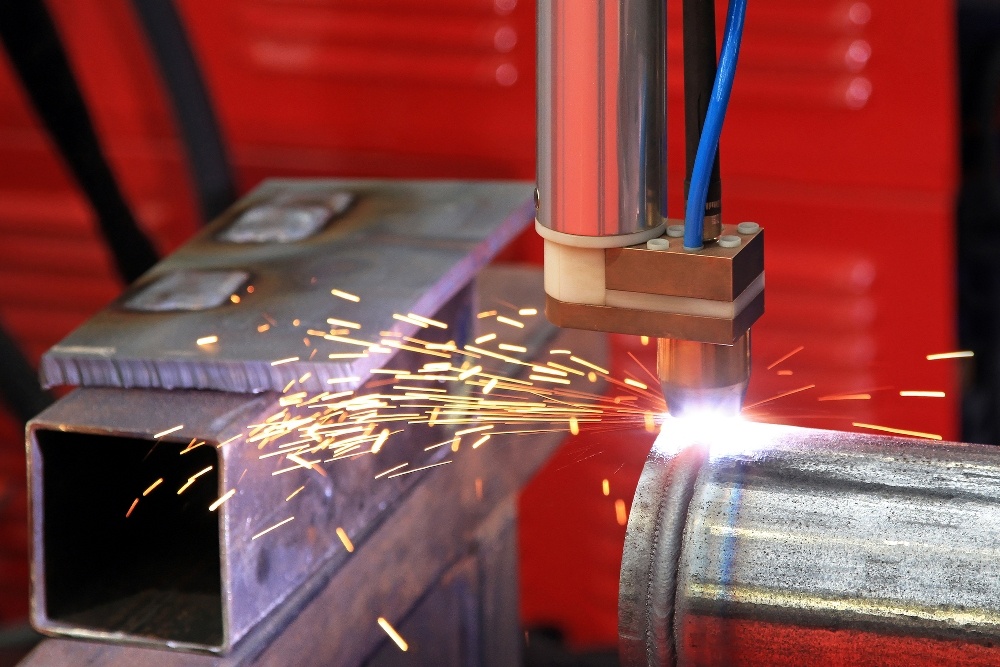

Metal fabrication uses a series of processes, such as welding and shaping, to create structures and components from raw materials, i.e., steel and metal.

It is the process of manipulating metal to create a structure or product.

From handrails to metal sculptures, metal fabrication covers it all.

Metal Fabrication Companies

When looking for the best fabricator, make sure to check out their:

Experience – What projects have they worked on in the past, i.e., what is their track record? Do these vary from large to small scale? Are there projects similar to yours to demonstrate experience in this area? Are they aware of industry regulations and standards? What are the most effective and efficient work processes?

Metal fabrication is a job role that requires a vast amount of specialist knowledge and technical skill – make sure your chosen fabricator has what it takes to work on your project.

Do they have the tools, equipment, and personnel to meet your requirements?

At Morfabrication, we have a wide range of experience across multiple projects – make sure to check out some of our work by viewing our case studies online or follow us on Facebook for more.

Capabilities – can they work from any drawing, translating these into valuable documents? Can they provide you with CAD designs based solely on your ideas? Can they work with various metals? Do they have capabilities in other areas, such as welding and cutting, or are these outsourced, and if so, how does this work?

Location – where exactly are the fabricators based? Do they have a factory unit that you can visit? This lets you confirm that they are indeed a legitimate business with business premises, and it enables you to see their work processes firsthand. Do they have adequate production space to meet your project specifications?

Customer service – customer service is everything, especially when someone else can be offering the same services, the level of customer service that metal fabricators offer is what can set them apart. Make sure they’re not just paying lip service to win the contract. Check out their online testimonials and reviews. Could you speak to previous customers? How quickly do they reply to your questions? Are you kept up to date regularly? The best fabricators go out of their way to ensure transparency in communication, especially when deadlines and price points come into play.

Quality of products and workmanship – What quality standards does the company uphold? Do they have any quality accreditations? What certificates do they hold? Do they take pride in their work? Monitor processes and inspect production.

Business improvement partners BSI recently conducted a robust audit of the Morfabrication environment, analysing internal systems and metal work processes to award Morfabrication the BS EN1090 ex-2 and ISO 9001 quality management system certifications.

With quality being such an important factor in choosing the best metal fabricators, make sure to check out our article on the benefits of quality control in fabrication.

Additional services – What other services does the team offer? Can they provide you with a complete solution, i.e., shaping, punching, welding, cutting, assembly, etc?

Equipment – do they have the right tools and resources to carry out the agreed metal works?

Pricing structure – is their pricing in line with others? Make sure to get a few quotes before settling on the first one, and remember the lowest price isn’t always the best. Make sure everything is broken down and itemised, and there are no hidden charges or costs.

Highest-quality fabrication services

Asking the right questions now can and will save you a considerable amount of time and resources in the future.

We understand that you want someone you can work with, someone you can trust. A team who can carry out projects to the highest of standards at the most cost-effective price points.

That’s why with years of combined experience, we’re proud to shout about our ability to produce high-quality products that meet and exceed expectations.

We like to think of ourselves as an extension of your team, and we aim to build long-lasting relationships that support good working practices.

Working collaboratively with you, we ensure you’re informed every step of the way.

Call us today on 0191 816 2718 or email your requirements to info@morfabrication.com