If your next project involves aluminium and requires complex cuts to achieve the final outcome, laser cutting will be a big part of the fabrication process.

However, aluminium’s highly reflective nature and high thermal conductivity make it one of the more challenging sheet metals to cut.

To ensure a high-quality cut and avoid the laser beam technology bouncing straight off the aluminium, causing serious problems, it’s essential that you work with professional and experienced sheet metal fabricators UK.

A team that you can work with, trust, and rely on to deliver you the highest quality finish while maintaining your project’s design integrity.

In this post, we examine some of the challenges of laser cutting aluminium and how these can be overcome.

What is aluminium laser cutting?

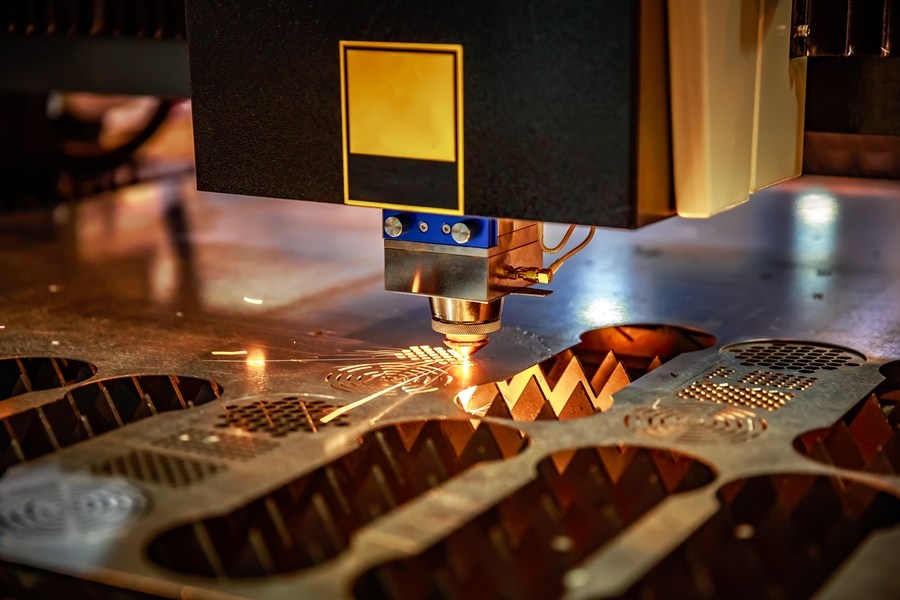

Laser cutting involves a beam of light heating/melting the metal in question, with the cuts then blown away by a blast of gas stream.

Laser cutting supports various industries, such as:

- Aerospace

- Automotive

- Electronics

- Signage

- Architecture

- And more.

Laser cutting is not a new concept in fabrication. In fact, laser cutting is one of the most commonly used processes a sheet metal contractor will use, as it is the one part of the fabrication process that allows you to cut intricate shapes and sheet metal to size, accurately, and to a high quality.

However, laser cutting aluminium involves a lot more precision and care due to aluminium’s reflective nature, which, depending on the grade of aluminium, will also affect the sheet metal’s reflectivity level.

Some sheet metal fabricators use a metal coating to help combat the reflection challenge, but this isn’t always an effective solution.

Guide to aluminium laser cutting

There are numerous challenges to be aware of when using various types of laser cutting technology for aluminium, these include:

In some instances, laser cutting aluminium can leave you with a burr (depending on the type of laser in use) which will then have to be mechanically removed. However, this can be avoided with the right team and the most appropriate equipment.

Aluminium is also more malleable, so laser beam cutting is not always effective at piercing the material and creating a first clean cut.

Aluminium absorbs heat quickly, making smooth laser processing difficult.

Thinner aluminium sheets may warp or distort, which can also lead to surface discolouration.

However, all is not lost. Aluminium can be laser cut safely, effectively, and to a high standard…

Solutions for using laser for aluminium cutting

Work with higher aluminium grades wherever possible, as these are much easier and straightforward to laser cut.

Opt for fibre lasers where appropriate, as they can provide you with more power, leading to better results. Fibre laser cutting uses optical fibres to deliver the cutting beam, which then melts and evaporates the aluminium, creating the cut. Fibre laser cutting is also suitable for cutting materials up to a thickness level of 25mm.

Ensure you set the right focal point distance. For aluminium, the focal point should be at the furthest end of the material.

It is not advisable to laser cut past a material thickness of 20mm with aluminium (unless using fibre lasers) as quality will be affected.

If you’re laser cutting past 8mm in diameter, consider water jet cutting technology for its speed, accuracy, and high quality.

If you choose to work with a C02 laser with a metal cutting head, ensure you have protection from spark reflection and adjust the focus ability to suit. C02 laser cutting is high power and low cost; however, be aware that reflection is a major challenge.

Plasma cutting is also suitable for aluminium. This fast and versatile process uses high-velocity ionised gas (plasma) jets to melt and remove the metal cut. However, you may experience rougher edges compared to when using a fibre laser.

Always make sure to clean the material and position it appropriately on the cutting table, setting the cutting parameters appropriately. You will then need to direct the laser beam onto the aluminium surface, using gas (nitrogen) to blow away the molten metal.

Benefits of laser cutting aluminium

- You can achieve precision and efficiency matched with consistency and quality when laser cutting aluminium.

- It is a versatile and cost-effective process, as the technique can be used on flat or formed parts of varying thicknesses and alloys.

- There is low wastage and minimal to no post-processing, removing the need for additional manufacturing stages.

- Laser cutting is fast and cost-effective.

- It offers clean and burr-free cuts.

- Laser cutting is easily integrated into the fabrication process and production line.

- Aluminium grades that benefit from laser cutting and offer good weldability and excellent machinability include: 6061, 5052, 5083, and 7075.

Sheet metal fabrication

At Morfabrication, we’ve fine-tuned our processes to ensure we use the most suitable cutting technology for the project in question.

All of our team are experienced and trained in laser cutting various sheet metals, and we work with your design specifications and requirements to achieve a quality outcome.

Whether you require CNC machining, laser cutting using fibre or C02 lasers, we’ve got you covered.

If you have a project coming up, get in touch with our team today and see how we can help you.