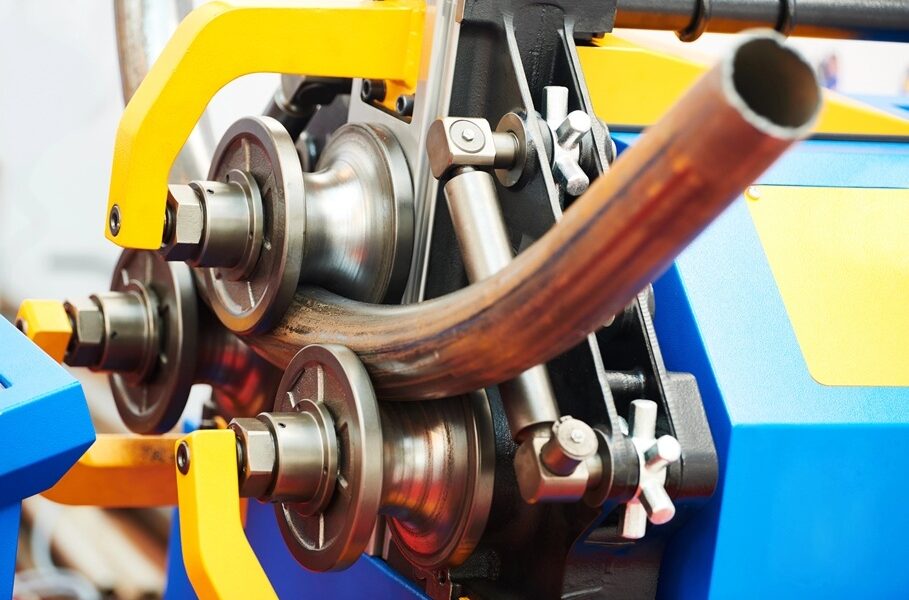

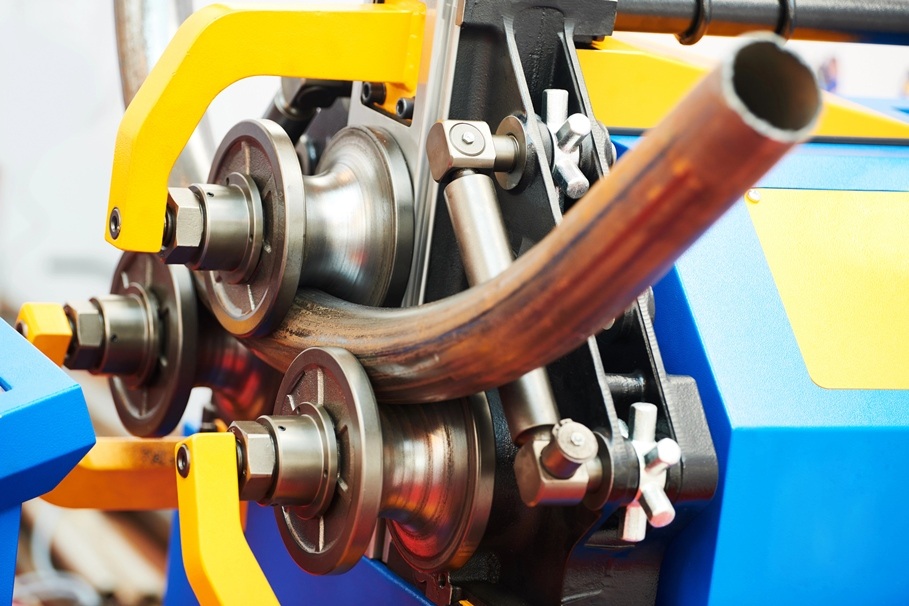

Tube bending is a fabrication process that, in its simplest form, shapes straight tubing into a curve.

A metal works process that bends tubes into different shapes, this type of sheet metal fabrication is essential for certain projects to help in the manufacture of set designs and requirements.

Providing a range of benefits, which we’ll explore further in this post, tube bending can be used across all sectors for various products and projects.

What is tube bending?

Tubes are hollow in shape and come in round, square, and oval forms, making them incredibly suitable for use in structural products/projects, mechanical applications, and pressure equipment.

In addition, pipes transport liquids and gases and have a specified diameter and wall thickness, making them suitable for applications involving pressure and temperature variations.

Tube bending is a precise fabrication process that involves changing straight tubes into various shapes and configurations designed to meet specific purposes and project specifications. It is also a requirement for pipework and tube fittings.

Note: It’s important to work with a professional and experienced fabrication team to achieve the perfect bend and meet specific tolerances and requirements.

Shapes you will find in tube bending are:

- Coil bend

- U bend

- L bend

- S bend.

The exact angle of the bend is based on set project requirements.

Types of tube bending

The fabrication process involves both hot and cold bending, applying pressure that applies stresses to straight tubing so it can be reconfigured.

Hot bending – the metal is heated to extreme temperatures to help with shaping and bending. By heating the material, the metal becomes softer and more flexible without breaking, allowing you to bend the tubing without applying intense force. However, metals can expand when heating, so steel metal fabricators will need to take into account changing dimensions if using this process.

Cold bending – bending/shaping is carried out at room temperature or just above. Cold bending offers a high level of accuracy as there is no change in the dimensions of the metal due to bending taking place at room temperature.

You must consider tubing material, tooling equipment/machinery use, and lubrication to achieve the perfect bend.

Tube bending works on different metals and alloys, including:

- Aluminium – most commonly used.

- Stainless steel – provides strength, abrasion resistance, and flexibility.

- Mild steel – an alloy that is strong and machinable.

- Brass – a polished material that provides strength and high corrosion resistance.

- Titanium – this is one of the best tubing materials around; it is lightweight, corrosion-resistant, and offers high tensile strength.

The process of tube bending

Before bending begins, it’s important to understand the tubing’s centre line radius, outside diameter, and wall thickness, as these elements affect tolerances.

Other bending variables to bear in mind include the inside and outside bend radius, centreline, and neutral line radius.

You must also consider spring back after bending and build this into bending specifications. Spring back is the percentage of the tube that springs back into its straight position after bending. Ideally, spring back should be as small as possible, and again, this will all depend on the materials you’re using and should be worked into your calculations.

If you’re working with a small tube radius, opt for tight-fitting and precise tooling to achieve a quality cut.

You will also need to know and build into account:

Weld seam – make sure to turn in to keep a good appearance.

Tube elongation – the maximum length a tube can be stretched before it breaks down.

Multiple bends – avoid bends over 90 degrees and keep sufficient distance between bends.

At the end of the bending process, other steel metal services may be required to add finishing touches to the final piece, such as cutting, deburring, welding, notching, etc.

Bending Techniques

There are various techniques that sheet metal fabricators (UK) use; these include:

- Press bending – the simplest form of bending, however, is only suitable for thinner tubes and pipes.

- Rotary bending – the most common form of bending and one of the best.

- Compression bending is an old-school bending technique that applies pressure on both ends of the tube.

Other tube bending techniques include:

- Ram bending

- Heat induction bending

- Roll bending

- Sanding pooling

- Hot slab forming

- Ring roll bending

Tubes have a very high structural integrity, so you can reshape tubing as a whole without the need to cut the tube. Today, with modern machinery and the latest software developments in CNC programming, tube bending can be very precise.

With the various ways tube bending can be carried out, choosing the right method for your application and project is vital.

As part of our range of sheet metal services, check out our latest post on metal rolling.

Sheet metal fabrication

Tube and pipe bending is used in various industries, such as:

- Automotive sector – exhaust systems, roll cages in rally cars, etc.

- Aerospace – adding structural integrity.

- Manufacturing industry – used in a range of machinery and tools.

- Construction – a requirement for skyscrapers and cranes.

- Agriculture – most suitable for farming equipment.

At Morfabrication, we work with a range of clients on tube bending, creating component parts for various projects.

Meeting specifications to a high standard and producing high-quality fabricated parts, our team uses their expertise and experience to achieve excellent precision.

Call us on 0191 816 2718 or email info@morfabrication.com to see how we can help you with your tube bending requirements today; we’d be happy to help.