Cutting, bending, and shaping metals requires a high level of precision fabrication.

It requires skill, specific equipment, and an understanding that more than one fabrication process may be required to achieve the desired result.

Producing custom and bespoke products and metal components for a range of industries and businesses of various sizes, we’re proud to offer a complete package of fabrication services – providing you with options to suit all of your requirements. Make sure to visit our page online to find out more.

When we begin to delve into custom sheet metal fabrication, things can become trickier.

Not because it is more challenging, but because there are numerous things to consider before diving straight in.

Of course, we know that stock sheet metal is the cheaper alternative, however, we also understand that cheaper doesn’t always lead to better AND stock sheet metal doesn’t always work.

That’s why below we’ve outlined the benefits of opting for custom sheet metal fabrication and what can be achieved when using this process.

Read on to see if custom sheet metal fabrication is the right choice for your next project.

What is sheet metal fabrication?

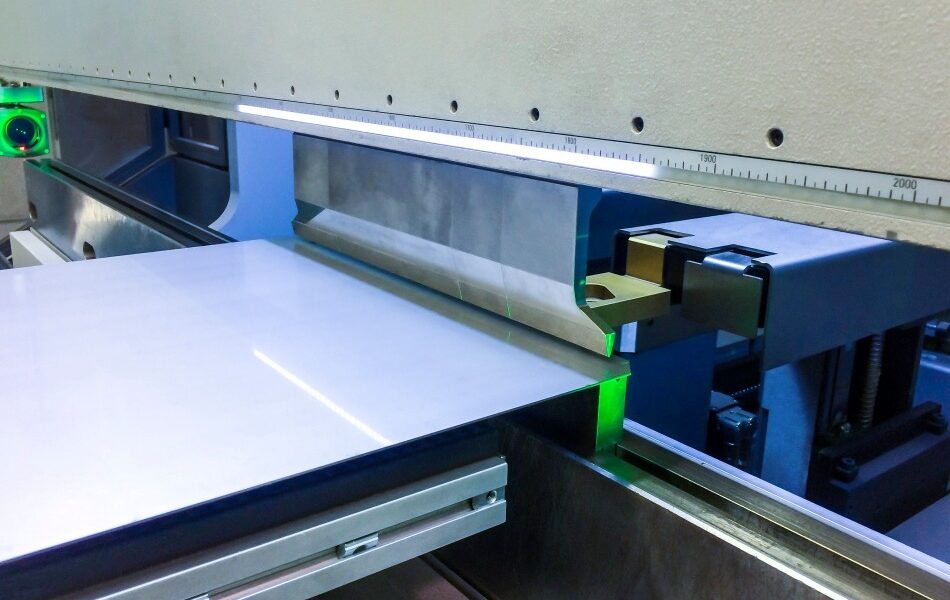

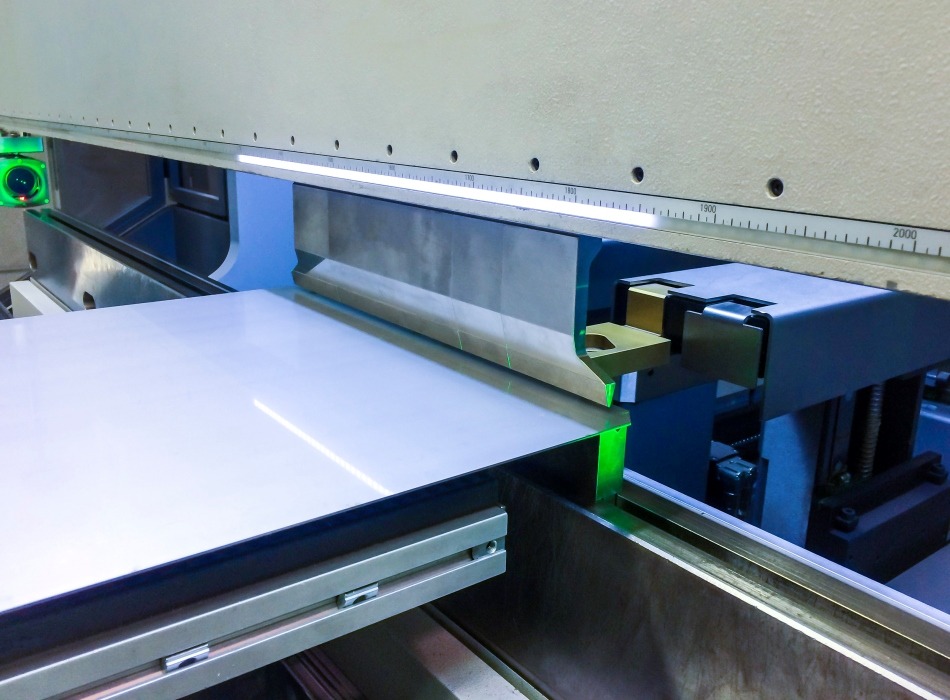

Sheet metal fabrication involves cutting, shaping, and forming metal into custom-made parts and components for use within other processes, products, or as a standalone product.

Sheet metal is lightweight, making it easy to shape and form and adaptable to meet a range of needs. It is also available in various weights and cost points.

Custom Sheet Metal Fabrication – The Benefits

Increased strength and durability

When sheet metal goes through a custom fabrication process, the end product will provide more strength and durability as it has been specifically designed for an intended purpose.

This means it will be able to withstand more than an average application.

Many businesses also rely on metal fabrication as the processes the metal goes through help to enhance durability.

It’s also worth noting that sheet metal is heat- and corrosion-resistant, allowing it to withstand extreme adverse weather conditions and natural events – again adding to its overall strength and durability.

Cost-effective

We’re not going to lie; custom fabrication is more costly than standard off-the-shelf components. However, the cost savings, in the long run, can far outweigh the initial investment.

How?

Because with custom fabrication, there is less need for maintenance, so there is less chance of any costly repairs. It has been designed and manufactured for a specific purpose, so it has been built to last.

Time efficient

Experienced and skilled metal fabricators will have the right machinery to do the best job.

For example, with CNC machinery, sheet metal can be cut and shaped with ease. With all cuts and shaping pre-programmed and controlled by computer software, you can achieve precise cuts and quality finishes quickly.

In addition, with a professional team, you can have all metal works fabricated just as you want, saving you time and resources from the start.

Customised to suit your requirements

The reason why custom sheet metal fabrication is so popular is because of skilled and trained bespoke metal fabricators.

For example, if you need various size components or you have really specific measurement requirements, off-the-shelf metal parts won’t always fit the bill.

However, due to the versatility of bespoke fabricators, you can now have products fabricated precisely to your specifications.

Maximises operational efficiency

When things are custom-made to support specific processes and production lines, it can help you boost the overall efficiency of internal processes and procedures, allowing you to finish projects quicker and meet customer demands and requirements faster.

Increased lifespan

Due to the specific customisation of sheet metal, it is designed and built to withstand the stresses of your applications.

Metal is also chosen specific to the chemicals, temperatures, and forces involved in your process, so you can have peace of mind that what has been manufactured has been made to last.

This leads us to…

Compatible with your components

Stock sheet metal forms aren’t always the most optimal, especially if you require more specialist materials and designs for your processes and products.

In these instances, customised sheet metal fabrication is for you.

Custom metal sheet fabrication allows you to produce parts that work with the systems you are using, catering to your specific needs, as we often find that stock sheet metal isn’t always compatible and most certainly doesn’t fit well.

Custom sheet metal fabrication near me

Always work with a professional and experienced team when looking for bespoke metal fabricators.

We would advise you to always do your research when opting for the right metal fabricator for you. Look for customer reviews and testimonials, case studies examining previous work, the quality of their craftsmanship, tools, equipment, and processes they use, and ultimately, how they will support your bottom line.

At MorFabrications, we cater to your needs, working to your specifications. We work with various businesses across a range of sectors, supporting clients with a range of metal

Works.

Using a variety of tools, techniques, and fabrication processes, we can help you with your specific manufacturing challenges.

Call us today at 0191 816 2718 or email info@morfabrication.com for further information.