Are you looking to turn ideas into reality?

Are you in need of a specific metal component for a particular application?

Do you want a cost-effective and seamless solution to metal fabrication?

Good sheet metal design can help.

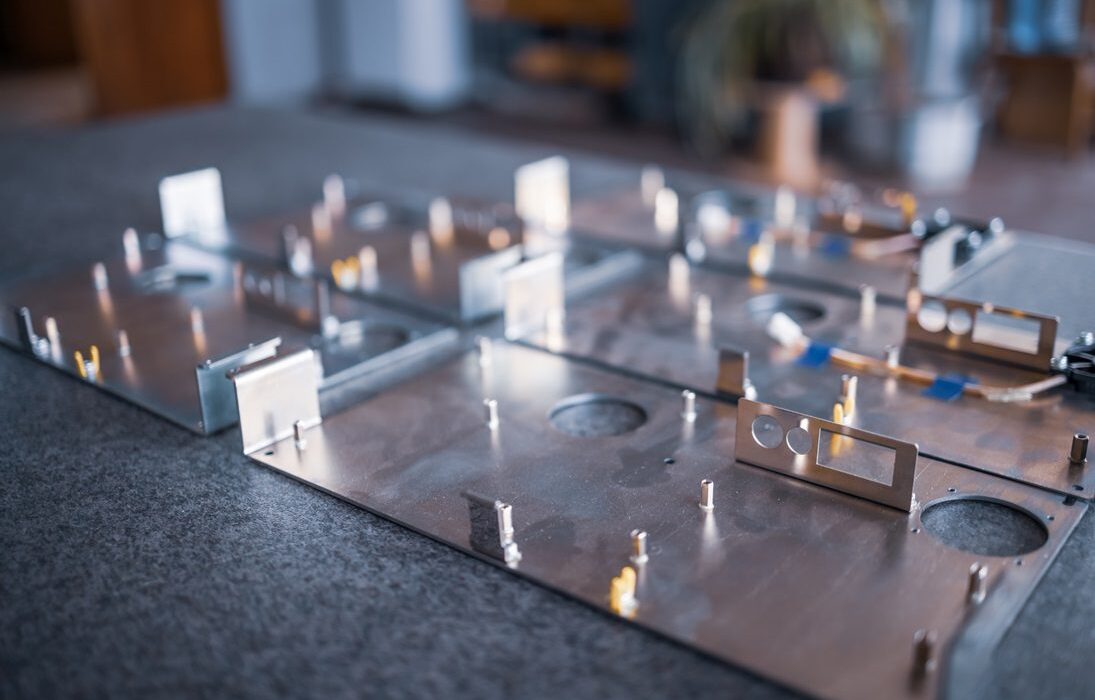

A process of designing components and metal structures from sheet metal to create lightweight, durable, and precision-engineered metal components is exactly what sheet metal design is.

And it is the first part of the process for a sheet metal fabrication company.

Crucial for many industries and applications, we explore hints and tips to ensure you get the most out of sheet metal design.

Sheet Metal Fabrication

Sheet metal design is suitable for industry sectors such as:

- Automotive

- Aerospace

- Architecture

- Electronics and more.

Some of the most common sheet metal materials include:

- Stainless steel

- Cold rolled

- Pre plated

- Aluminium

- Copper

- Brass.

Using CAD software to create 3D models sheet metal design is essential to ensure that any tweaks or changes that need to happen happen before the sheet metal goes into full production, costing you money and additional resources.

Ideally, you want sheet metal to flow through a continuous process without hitting any bumps in the road, as this will improve lead times and lower your overall project costs.

So how can you do this, and what areas should you consider?

Sheet Metal Design Tips

Sheet metal design is intricate. There are a lot of different and moving parts to the puzzle.

These tips can help to ensure a smoother experience and ultimately optimise designs for manufacturing.

Tips for sheet metal design:

Design for manufacturability – collaboration is key as you work with your chosen sheet metal fabricators, understand their capabilities and processes, and look to align design with certain manufacturing methods. This approach provides insight into what can be achieved and minimises complications, reduces costs, and streamlines production as you know what you’re working with.

Choose your material carefully – it is vital that you choose the right material for your application and metal component. Think about the levels of strength required, flexibility, whether the metal has to be corrosive resistant, weather resistant, etc. What sheet metal thickness is required? Even weight? All of these should be built into the design to allow your fabricator to choose the right material for your application.

Simplify bending – bending and forming is one of the most common fabrication processes, and we would always advise design to keep a consistent bend radius in mind. Look to avoid sharp corners and tight radii in order to reduce cracks and deformation.

Minimise welding and the need for additional fasteners – by simplifying assembly, you can reduce your overall manufacturing costs. For example, could designs be formed from a single sheet? Are there other, more cost-effective methods to secure connections?

Consider hole sizes – if punching is required and holes are part of the design, then ideally, the diameter of the hole should be equal to or more than the thickness of the sheet metal. In addition, consistent hole size diameters on a product can speed up production.

Simplify the folds – the more complicated the design, the more expensive it will be to manufacture. Look to design simple angled bends, ideally with a radius equal or greater than the thickness of the sheet.

Consider tooling and equipment – tool availability can limit a part’s shape and design structure. Designs that are considered standard sizes will attract lower costs and faster manufacturing times.

Avoid tight tolerances – tight tolerances are generally more expensive, so it is advisable to only assign these to features and surfaces that are critical to the functionality of a part.

Streamline assembly – more manufacturing than design but should still be carefully considered. Parts should fit together perfectly, especially to help reduce the risk of errors.

Benefits of good sheet metal design tips

Good sheet metal design carried out by experienced fabricators provides you with:

Design efficiency – by optimising your designs, you can enhance the overall functionality of the end product. Due to careful consideration going into material selection, i.e., material thickness, tolerances, etc, you can also improve manufacturability and cost-effectiveness.

Seamless manufacturing process – as your design is finalised, you can nail down exactly what fabrication processes will be used to make the design a reality. With everything so meticulously planned, this will save you time and money.

Reduction in manufacturing costs – because you have streamlined the fabrication process to make a more efficient production line and minimise waste, manufacturing costs will be lower as a result.

Customised metal products – designs allow you to customise production and tailor structure, aesthetics, and functional criteria based on the design specification using the latest advancements in sheet metal fabrication techniques.

Expertise – By collaborating with a professional sheet metal fabrication company, you have access to their knowledge and experience and that of their team.

Sheet metal Fabrication

The tips mentioned above are only a handful of considerations that must go into sheet design. However, the aims are the same: to reduce production costs, boost efficiency, and ensure a smoother fabrication process.

At Morfabrication, we aim to optimise sheet metal design to ensure an efficient fabrication process and an effective, high-quality end product.

With years of experience and knowledge, we provide you with high-value and quality sheet metal products.

Call us today on 0191 8162718 to see how we can support your sheet metal requirements.